Concrete steels

Product dimensions:

“Neven-komerc” doo in its assortment has hot rolled smooth and ribbed concrete steel – Rods, straightened, standard thicknesses of diameter ( mm ): 5, 6, 8, 10, 12, 14, 16, 18, 20, 22, 25

length for smooth concrete steel (u mm): 6000, 12000

diameter of coil for smooth concrete steel (u mm): 5,5 – 14

length for ribbed concrete steel (u mm): 12000

diameter of bars of ribbed concrete steel (u mm): 8 – 32

On request possible cut to measure.

Tolerances are prescribed by the standard C.K6.120

Product specifications:

Chemical and mechanical properties are up to standard C.K6.020

Reinforcement networks have a very wide application in construction: in high-rise construction (foundations, slabs, walls, stairs), in civil engineering (roads, bridges, retaining walls, tunnels), hydraulic (dams, canals, collectors), for the manufacture of various types of reinforced concrete elements and more.

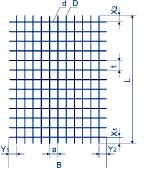

Dimensions of the net:

- a – axial distance of longitudinal wires (mm) a = 100+25n, n= 0,1…..8 mm

- t – the axial distance of the transverse wires (mm) t = 50+25n, n= 0,1…..14 mm

- condition: t < 3a i ( a+t ) < 400 mm

- L – length of the net (mm) 2,5 < L < 8,0 m

- B – net width (mm) 1,5 < B < 2,45 m

- D – diameter of longitudinal wires (mm)

- d – the diameter of the transverse wires (mm) 1,5 > d/D > 0,51

- X1, X2 – indentation of longitudinal wires (mm) X1 = X2 = t/2 > 50 mm

- Y1, Y2 – culvert of the transverse wires (mm) Y1 = Y2 = a/2 > 25 mm

The product range includes numerous combinations of longitudinal and transverse wires and their distances between them and can be:

- transversely load-bearing, T – grids, the wires are crossed in the shape of a rectangle (a > t), whereby the transverse wires are supported

- mutually wearable, Q – nets, the wires are crossed in the form of a square (a=t), and the longitudinal and transverse wires are supported

- nets for vertical wall construction, Qx – The net is identical to the Q network, except that the passes on one side are much longer than those on the other, and they are defined according to specific needs.

- special net on special order, S – mreže

Tolerances allowed

The production, delivery and quality control of a welded reinforcement mesh is prescribed by the standard U.M1.090.

The quality control of the cutting rods is performed by testing the mesh for: tensioning according to the standard EN10002-1and bending to standard C.A4.005.Transverse load-bearing, T-nets

| Net tag (type) | Wire diameter | Wire distance | The dimension of the network | The mass of the net | ||||

| Longitudinal D | Transverse d | Longitudinal a | Transverse t | Length L | Width B | Per m2 | Piece | |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (Kg/m2) | (Kg/m2) | |

| T 257 | 5,0 | 7,0 | 250 | 150 | 6000 | 2150 | 2,685 | 34,631 |

| T 378 | 5,0 | 8,5 | 250 | 150 | 6000 | 2150 | 3,647 | 47,052 |

| T 524 | 5,0 | 10,0 | 250 | 150 | 6000 | 2150 | 5,093 | 65,701 |

Double-sided, Q-nets (according to U.M1.091)

| Net tag (tip) | Wire diameter | Wire distance | The dimension of the net | The mass of the net | ||||

| Longitudinal D | Transverse d | Longitudinal a | Transverse t | Length L | Width B | Per m2 | Piece | |

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (Kg/m2) | (Kg/m2) | |

| Q 84 | 4,0 | 4,0 | 150 | 150 | 6000 | 2150 | 1,364 | 17,598 |

| Q 92 | 4,2 | 4,2 | 150 | 150 | 6000 | 2150 | 1,502 | 19,376 |

| Q 111 | 4,6 | 4,6 | 150 | 150 | 6000 | 2150 | 1,791 | 19,446 |

| Q 126 | 4,0 | 4,0 | 100 | 100 | 6000 | 2150 | 2,023 | 26,098 |

| Q 131 | 5,0 | 5,0 | 150 | 150 | 6000 | 2150 | 2,122 | 27,375 |

| Q 139 | 4,2 | 4,2 | 100 | 100 | 6000 | 2150 | 2,227 | 28,730 |

| Q 166 | 4,6 | 4,6 | 100 | 100 | 6000 | 2150 | 2,657 | 34,279 |

| Q 188 | 6,0 | 6,0 | 150 | 150 | 6000 | 2150 | 3,059 | 39,463 |

| Q 196 | 5,0 | 5,0 | 100 | 100 | 6000 | 2150 | 3,147 | 40,596 |

| Q 221 | 6,5 | 6,5 | 150 | 150 | 6000 | 2150 | 3,583 | 46,219 |

| Q 238 | 5,5 | 5,5 | 100 | 100 | 6000 | 2150 | 3,821 | 49,295 |

| Q 257 | 7,0 | 7,0 | 150 | 150 | 6000 | 2150 | 4,162 | 53,684 |

| Q 283 | 6,0 | 6,0 | 100 | 100 | 6000 | 2150 | 4,537 | 58,521 |

| Q 331 | 6,5 | 6,5 | 100 | 100 | 6000 | 2150 | 5,313 | 68,538 |

| Q 335 | 8,0 | 8,0 | 150 | 150 | 6000 | 2150 | 5,443 | 70,216 |

| Q 378 | 8,5 | 8,5 | 150 | 150 | 6000 | 2150 | 6,132 | 79,104 |

| Q 385 | 7,0 | 7,0 | 100 | 100 | 6000 | 2150 | 6,171 | 79,610 |

| Q 424 | 9,0 | 9,0 | 150 | 150 | 6000 | 2150 | 6,876 | 88,702 |

| Q 442 | 7,5 | 7,5 | 100 | 100 | 6000 | 2150 | 7,090 | 91,473 |

| Q 503 | 8,0 | 8,0 | 100 | 100 | 6000 | 2150 | 8,072 | 104,126 |

| Q 524 | 10,0 | 10,0 | 150 | 150 | 6000 | 2150 | 8,502 | 109,678 |

| Q 567 | 8,5 | 8,5 | 100 | 100 | 6000 | 2150 | 9,093 | 117,306 |

| Q 577 | 10,5 | 10,5 | 150 | 150 | 6000 | 2150 | 9,370 | 120,877 |

| Q 636 | 9,0 | 9,0 | 100 | 100 | 6000 | 2150 | 10,197 | 131,542 |

| Q 709 | 9,5 | 9,5 | 100 | 100 | 6000 | 2150 | 11,362 | 146,567 |

| Q 785 | 10,0 | 10,0 | 100 | 100 | 6000 | 2150 | 12,608 | 162,647 |

Reinforcement mounts, binor

Reinforcing bars – binor are made of cold drawn wire (smooth or ribbed) that meets the mechanical characteristics prescribed by the standard SRPS C.B6.013. Depending on the type of bracket, there are two and four bars, respectively, in the lower belt, one in the upper belt and interconnected by bent diagonal bars that are welded electrically to the upper and lower belts. They are used in construction mainly for floor and roof structures in high-rise buildings, such as for example. residential buildings, industrial halls, public buildings (hospitals, schools, etc.).

Product Specifications:

Chemical and mechanical properties are up to standard C.B6.013

stretching limit min. Re = 500 N/mm2

tensile strength min Rm = 560 N/mm2

elongation min A = 6%